Business

Technology

Slimming

Laser

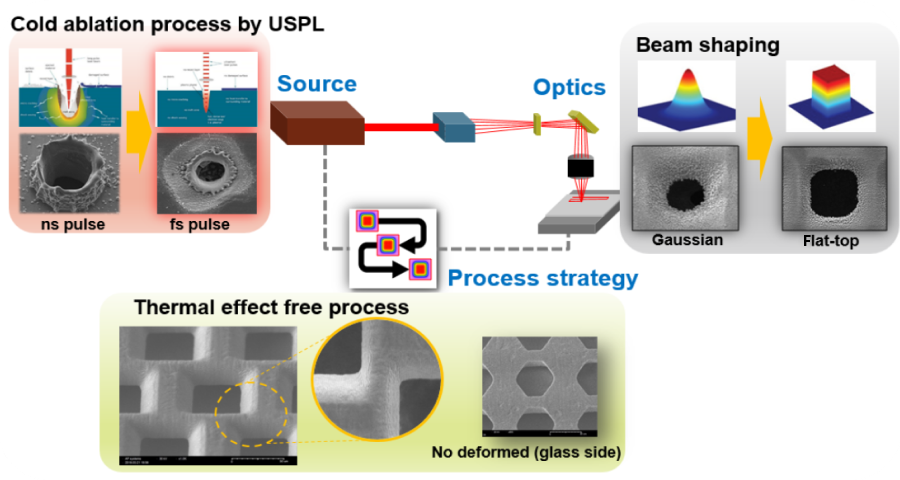

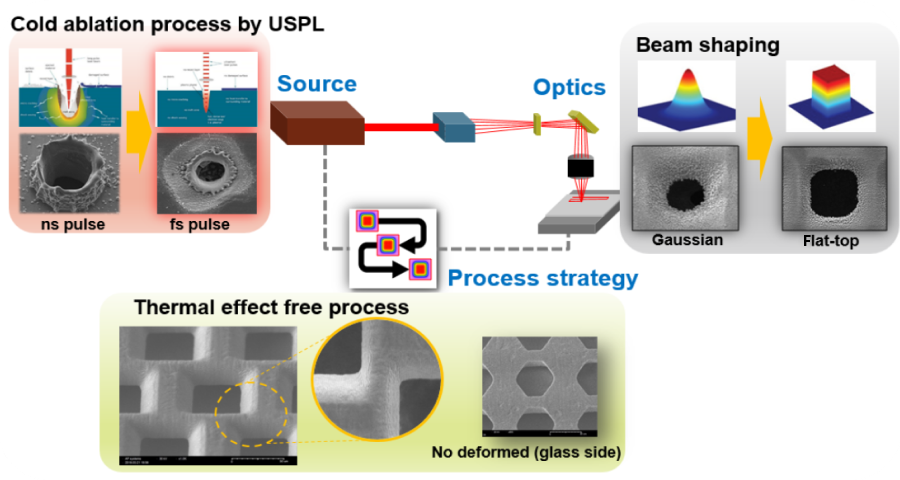

Key Process Feature of Fine Patterning

Feature

Fine Laser Patterning

Total Solution

Various High-precision Products

Cleaning

Inspection

Slimming

Laser

Key Process Feature of Fine Patterning

Fine Laser Patterning

Total Solution

Various High-precision Products

Cleaning

Inspection